Electric motor windings for pumps: efficiency and long life in industrial applications

In industrial settings, pumps are critical to maintaining continuous production processes. Whether in water lifting systems, cooling circuits, or equipment handling corrosive or high-temperature fluids, uninterrupted operation is essential.

The importance of electric motor windings for industrial pumps

The operating conditions of pumps are often extreme: frequent starts, long continuous duty cycles, variable loads, mechanical vibrations, and exposure to moisture, dust, or aggressive chemicals. A winding designed and manufactured without accounting for these factors can quickly become a weak point in the entire system.

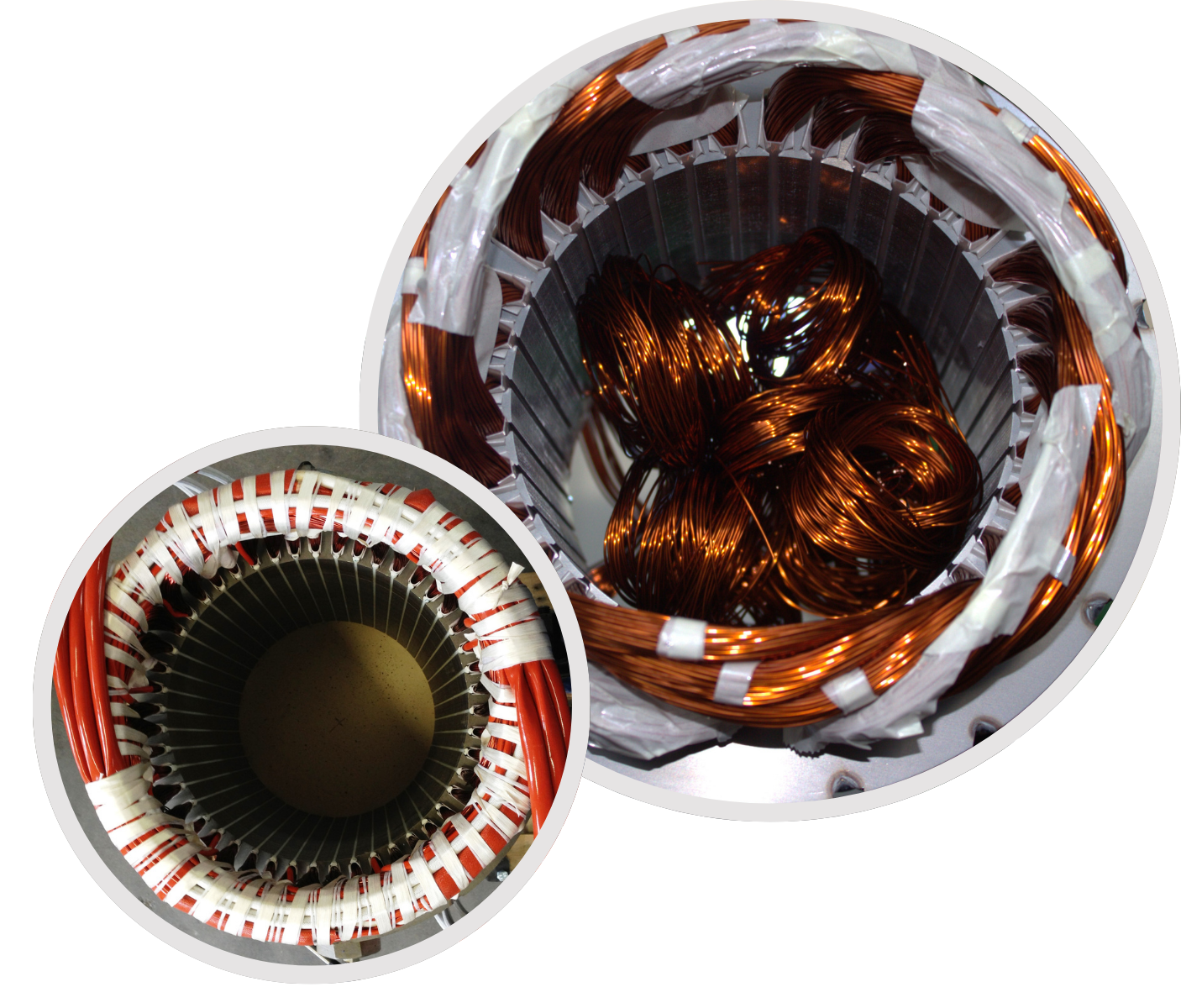

Zampolli Avvolgimenti produces fully custom electric windings, precisely following the construction drawings provided by the customer. Depending on the pump type, centrifugal, positive displacement, submersible, or lobe, and the fluid being handled, we select the most suitable materials and technologies to ensure a result perfectly aligned with the application’s requirements.

The technical advantages of our electric motor windings for pumps

Choosing a Zampolli winding means enhancing motor performance and extending service life, while minimizing failures and unplanned downtime.

Key benefits include:

- reinforced insulation, using certified Class H and higher-grade materials to withstand the most demanding electrical and thermal stress;

- full compatibility with inverters and frequency converters, ideal for variable-speed pumps and dynamic operating cycles;

- thermosetting resin impregnation, essential to compact insulating materials, eliminate internal vibrations, and ensure long-term winding integrity;

- 100% manual construction, allowing precise coil placement and accurate copper distribution with extremely tight tolerances.

Every pump winding undergoes rigorous testing, including insulation checks, electrical resistance measurements, and functional verification with high-precision instruments. This ensures complete reliability even under the most critical operating conditions.

Discover our all sectors

Why choose Zampolli for electric motor windings in industrial pumps

For more than fifty years, Zampolli Avvolgimenti has been a trusted partner for manufacturers of electric motors used in industrial pumps. Our strength lies in a high-precision, craftsmanship-based approach, combined with solid technical expertise and meticulous attention to every construction detail.

By choosing us, you benefit from:

- high-quality materials, selected to withstand aggressive fluids, humid environments, and elevated temperatures;

- fully manual production, carried out by skilled specialists who ensure superior precision compared to automated processes;

- flexible manufacturing, allowing us to handle both small batches and complex prototypes with equal care;

- stringent final inspections, performed on every single winding before delivery;

- strict compliance with technical specifications, tailored to the pump application and the customer’s requirements.

Our mission is to deliver reliable, long-lasting electric windings that ensure continuous, safe pump operation, reduce maintenance costs, and enhance the overall value of the installation.

Do you need more info about our products?

We can produce a very wide range of asynchronous windings thanks to dedicated but flexible equipment.