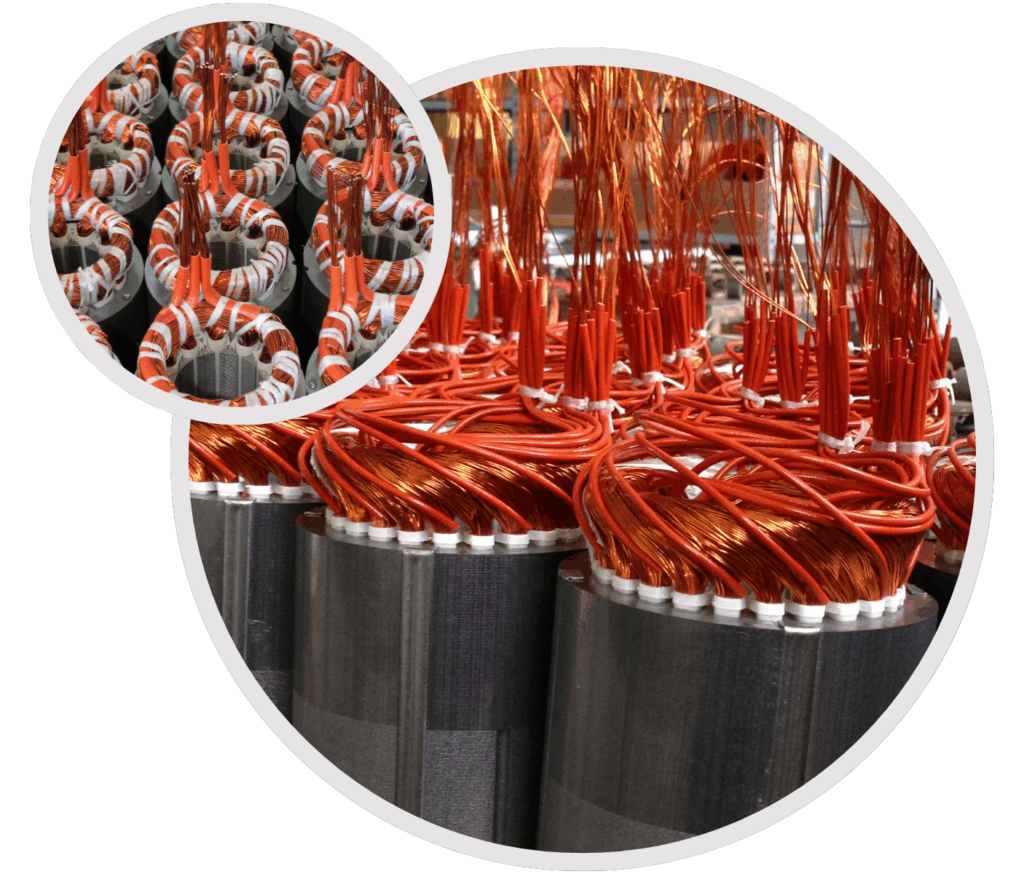

Electric motor windings for electric traction

AC motors for electric traction are engineered to deliver high performance in applications where energy efficiency, durability, and reliability are non-negotiable. In industrial contexts, traction systems must operate under demanding conditions while ensuring consistent performance and long service life.

Avvolgimenti Zampolli meets these challenges with tailor-made solutions, designed to integrate seamlessly into motors used across a range of sectors, including construction, agriculture, logistics, and urban mobility.

Our windings combine high efficiency and reliability with minimal maintenance requirements, helping to significantly reduce operating costs.

The specific demands of electric traction

Electric traction applications demand motors capable of operating reliably even in harsh environments. That’s why winding quality is critical, it must be crafted with absolute precision, using high-grade materials that meet the specific standards of each application.

Energy efficiency is another key priority. Reducing weight, minimizing energy consumption, and extending operational range are essential goals, particularly for battery-powered and electric vehicles. Compact design is equally important: motors must fit into tight spaces without compromising power or durability.

Thanks to their versatility and adaptability across a wide range of voltages and power levels, Zampolli windings are ideal for numerous applications, from vehicle propulsion to industrial material handling.

Advanced coil winding technologies for electric traction motors

Winding quality is the foundation for producing long-lasting, high-performance electric motors. At Avvolgimenti Zampolli, we combine advanced technologies with precision manual craftsmanship to deliver high-efficiency windings that lower operational costs and reduce environmental impact.

Every component is carefully selected, from enamelled copper conductors to insulating materials compliant with international standards such as REACH and RoHS. The result is a durable, dependable product that fully meets regulatory requirements.

We also offer full customization of winding configurations, allowing us to fine-tune each project to the customer’s specific performance, thermal, and mechanical needs.

Main applications of our electric motor windings in traction systems

Our electric motor windings are used across a wide variety of traction-related applications. They power motors in vehicles for construction and agriculture, industrial logistics systems, professional cleaning equipment, and even marine, railway, and airport applications.

Other use cases include motors for lifting equipment, such as forklifts, cranes, and pallet trucks, electropumps for hydrostatic drives, and motors for industrial automation.

Urban e-mobility is one of the fastest-growing segments. Our windings are employed in wheel hub motors, steering gear motors, and traction motors for city cars, e-bikes, electric scooters, go-karts, and hybrid vehicles.

Every solution is designed to deliver maximum efficiency, even at variable speeds, with particular focus on compactness and overall system sustainability.

Discover all our sectors

Why choose Zampolli for electric traction project

Avvolgimenti Zampolli has been active in the electric traction winding sector for over 20 years. We were among the first in Italy to recognize the potential of this market, developing specific expertise in the production of low-voltage windings for traction applications.

Each project is developed in close collaboration with the client to ensure a unique, high-performance solution. This is complemented by over half a century of experience in the craft of coil winding, a heritage built on precision and meticulous attention to detail.

Thanks to our flexible manual processes, we are able to manage even the most complex orders, maintaining the highest quality standards and delivering results that fully meet customer expectations.

Do you need more info about our products?

We can produce a very wide range of asynchronous windings thanks to dedicated but flexible equipment.