Electric motor windings for spindle motors

In applications where repeatability, micrometric precision, and high rotational speeds are daily requirements, electrospindles performance must remain consistent and robust.

These systems often operate at the edge of their thermal and mechanical limits, demanding electric motor windings for spindle motors that are engineered to withstand extreme conditions and tight tolerances.

The importance of high-quality windings for industrial electrospindles

The spindle motor is one of the most critical and sensitive components in any CNC machine tool. Constantly exposed to mechanical stress and thermal loads, it requires internal components capable of delivering stable performance even in the harshest conditions. Among these, the electric winding plays a decisive role.

A winding designed for high-speed, high-precision operation must offer durability, mechanical resistance, and thermal stability to ensure process repeatability. Effective motor cooling is equally essential to prevent overheating, which could compromise both accuracy and reliability.

For these reasons, spindle motor windings cannot be manufactured using standardized processes. They demand tailored design choices, premium materials, and refined craftsmanship.

Technology and manufacturing processes for spindle motor windings

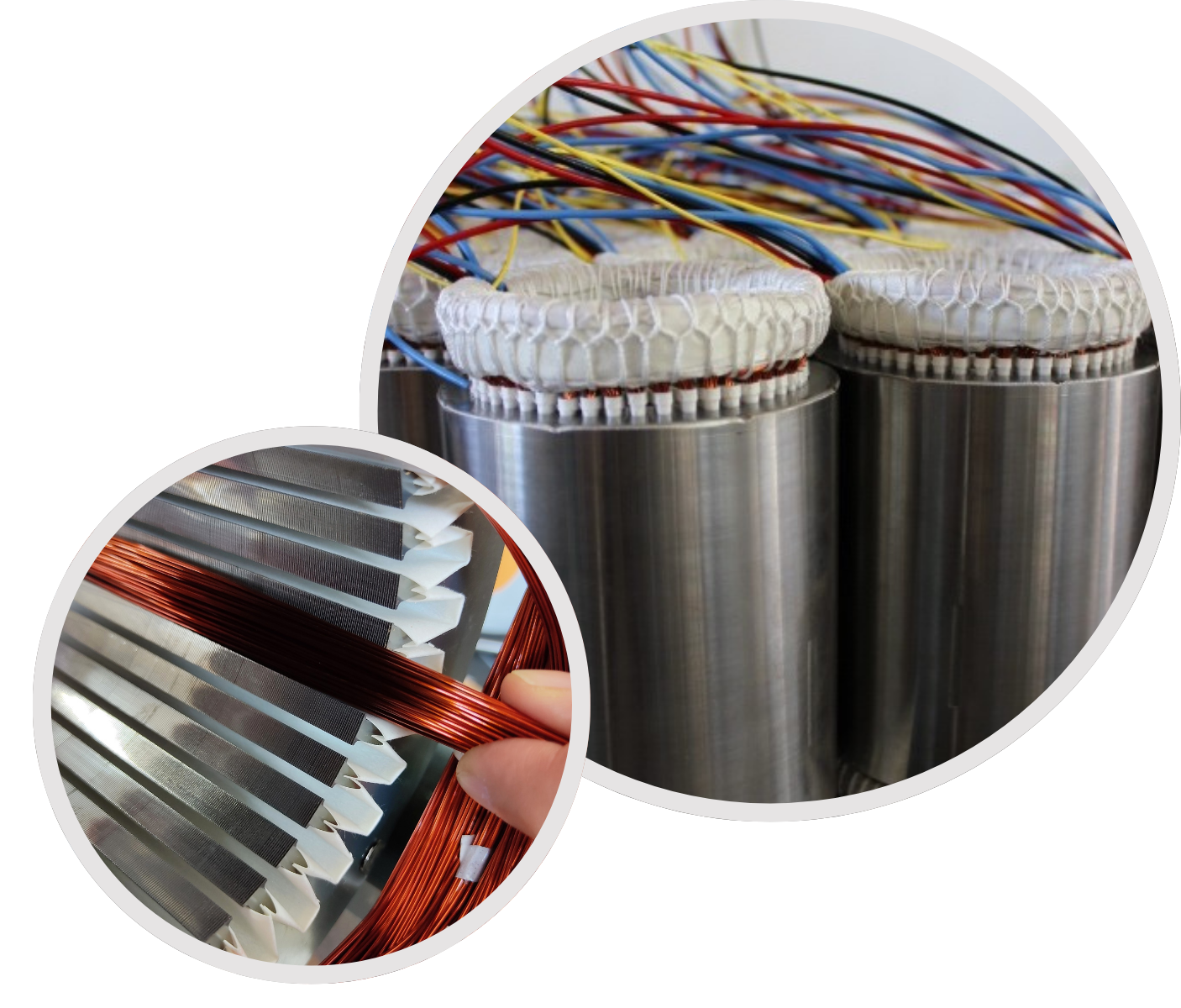

Manufacturing electric motor windings for spindle motors requires a high degree of specialization. At Avvolgimenti Zampolli, every step is carried out under strict construction standards. Coils are inserted by hand to allow for precise positioning, minimizing tolerances and ensuring consistent phase alignment.

We use only certified materials that fully comply with international standards. The result is a winding that guarantees stable, high-level performance, perfectly suited to the functional demands of next-generation electrospindles.

Quality standards and testing of spindle motor windings

One of Zampolli’s key strengths is our rigorous quality control protocol. Every winding is thoroughly inspected to ensure optimal copper distribution, an essential factor for magnetic efficiency and reduced energy losses.

Special attention is given to phase insulation, a critical aspect for component safety and reliability. During final testing, each winding undergoes a series of precision measurements to detect even the smallest irregularities. Our process is designed not only to meet industrial standards, but also to exceed the expectations of our most demanding customers.

Discover all our sectors

Why choose Zampolli for your CNC spindle motor windings

Partnering with Zampolli means relying on a company that combines over 50 years of artisanal experience with a cutting-edge technical approach. Each winding is custom-built, starting from a detailed analysis of the application’s technical requirements.

Our solutions are fully customizable, and each production stage is carried out manually to guarantee maximum accuracy. This attention to detail extends to the insulation system, which is handled with extreme care, and to the exclusive use of certified materials that meet all regulatory standards. Final testing is conducted with advanced equipment, maintaining tolerances below 2%, a clear indicator of the high level of quality we deliver.

At Zampolli, every project reflects solid technical know-how, flexible production capabilities, and a genuine passion for precision craftsmanship. It’s this mindset that allows us to meet the expectations of manufacturers working with high-performance spindle motors.

Do you need more info about our products?

We can produce a very wide range of asynchronous windings thanks to dedicated but flexible equipment.