Electric motor windings for automotive: custom solutions for outstanding performance

The automotive industry is undergoing a profound transformation driven by the rapid adoption of electric motors. Energy efficiency, environmental sustainability, and dynamic performance are becoming the new benchmarks for next-generation vehicles.

In this scenario, electric motor windings for automotive applications are one of the most strategic components in designing high-performance, reliable propulsion systems.

Advanced technologies for high-quality automotive windings

The range of technical solutions available for electric motor design in the automotive sector is vast and constantly evolving. There is no one-size-fits-all technology: selecting the right type of winding, materials, and structural geometry depends on multiple interrelated factors.

These include the vehicle’s required performance, the chosen electrical architecture, total weight, energy recovery strategy during braking, and the projected production volume.

Driven by continuous innovation from car manufacturers, the automotive sector is in a state of constant R&D activity. New materials, improved processes, and more efficient design solutions are introduced regularly, creating a highly dynamic technical landscape.

However, in premium segments such as luxury and motorsport, standardization gives way to a radically different approach. Here, the focus shifts from mass production optimization to tailor-made solutions that aim for peak performance.

This is where technical craftsmanship becomes a decisive factor, built on decades of experience, a collaborative mindset, and the ability to tackle complex engineering challenges with flexibility and vision.

Customization and rapid prototyping for automotive electric motors

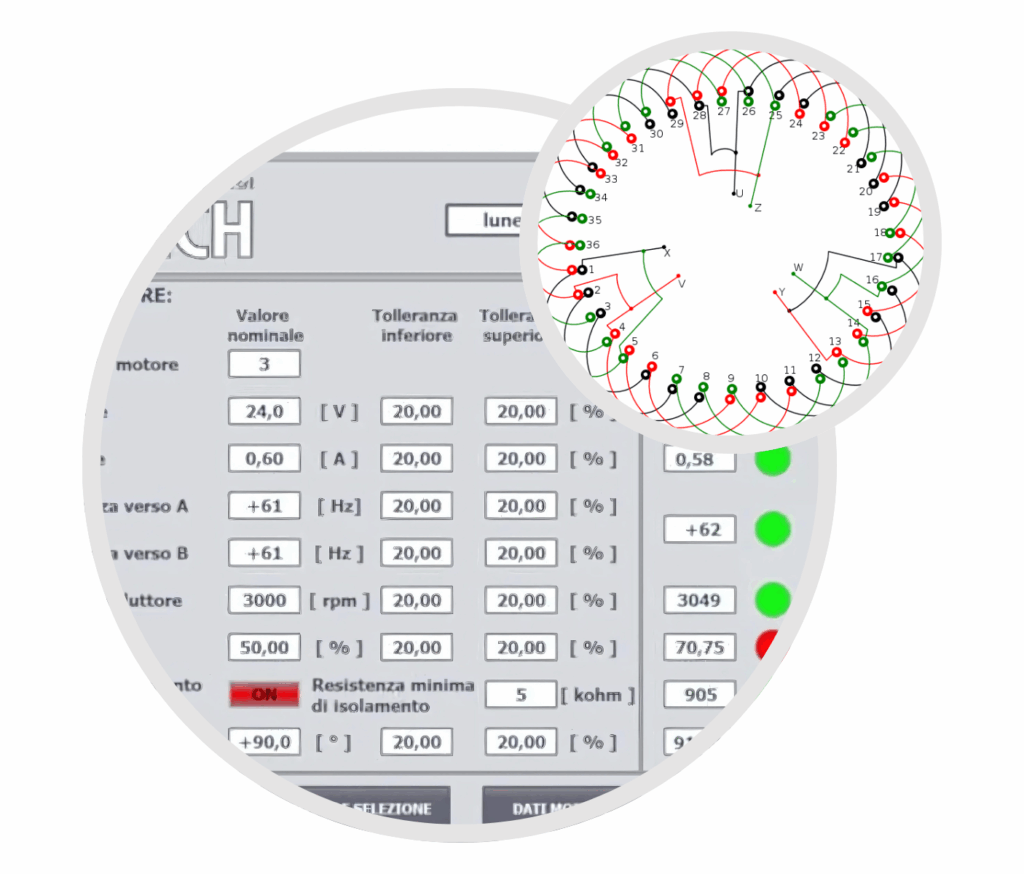

To meet these high standards, Avvolgimenti Zampolli positions itself as a technical partner in the development of custom electric motor windings for automotive applications. We support clients from the earliest design phases, assisting in the selection of the most suitable materials, testing their machinability, and validating them directly on prototypes.

Our goal is to guide each project toward the optimal construction solution, aligned with functional, thermal, and electrical requirements.Every project is unique. That’s why we’re not afraid to adapt or rethink even our most established processes to better suit specific needs.

Experimentation is embedded in our approach: we carry out functional trials to verify product compliance with project parameters, fine-tuning as needed until we reach the ideal performance.

This iterative process, supported by continuous feedback with the client, allows us to accelerate development timelines, reduce errors, and optimize the balance between time, cost, and technical performance. Prototyping becomes a space for active, constructive exchange, where our expertise meets the client’s design vision.

Discover all our sectors

Why choose Zampolli for your automotive projects

Our team combines the precision of seasoned professionals with the attention to detail of master craftsmen. We manage the entire development process, ensuring both deadlines and quality standards are met.

We are the ideal partner for automotive projects focused on small production runs or even unique prototypes. By working closely with our clients’ engineering teams, we foster an ongoing, constructive dialogue that helps us respond to even the most complex design challenges, quickly and flexibly. Thanks to our agile production structure, we can react swiftly to requests, streamline development times, and deliver custom solutions without compromising on quality.

Choosing Zampolli for your electric motor windings for automotive applications means relying on a solid, responsive, and highly skilled partner. A company where attention to detail is the starting point for solutions that truly make a difference, on the road and on the track.

Do you need more info about our products?

We can produce a very wide range of asynchronous windings thanks to dedicated but flexible equipment.