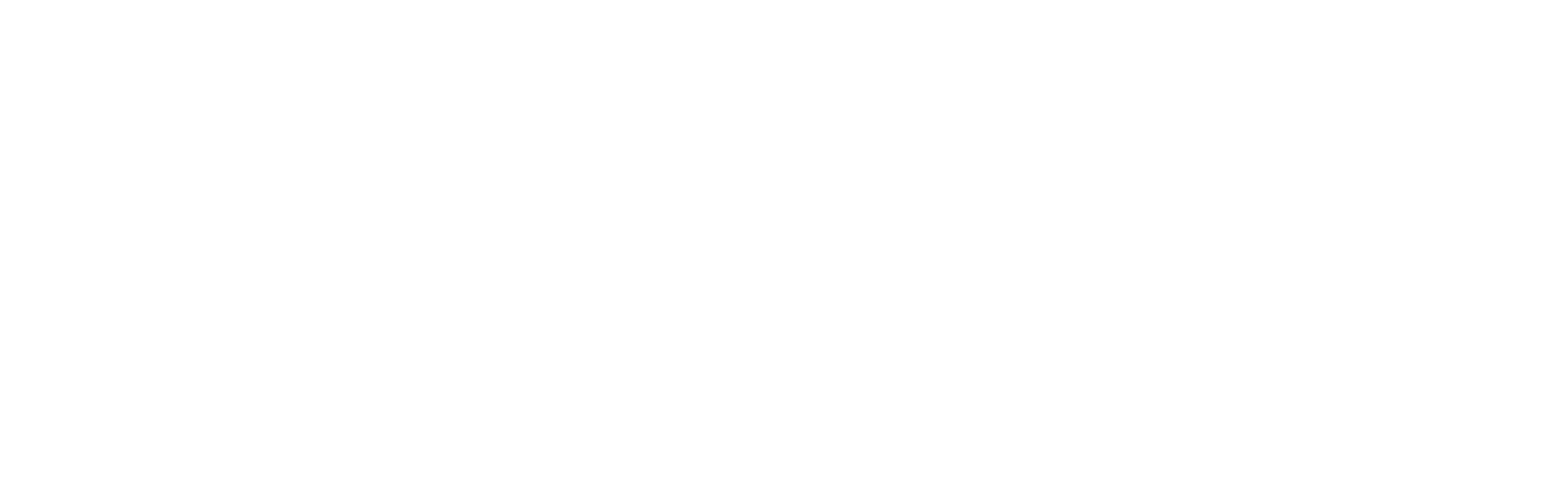

Electric motor windings for machine tools: outstanding performance for precision mechanics

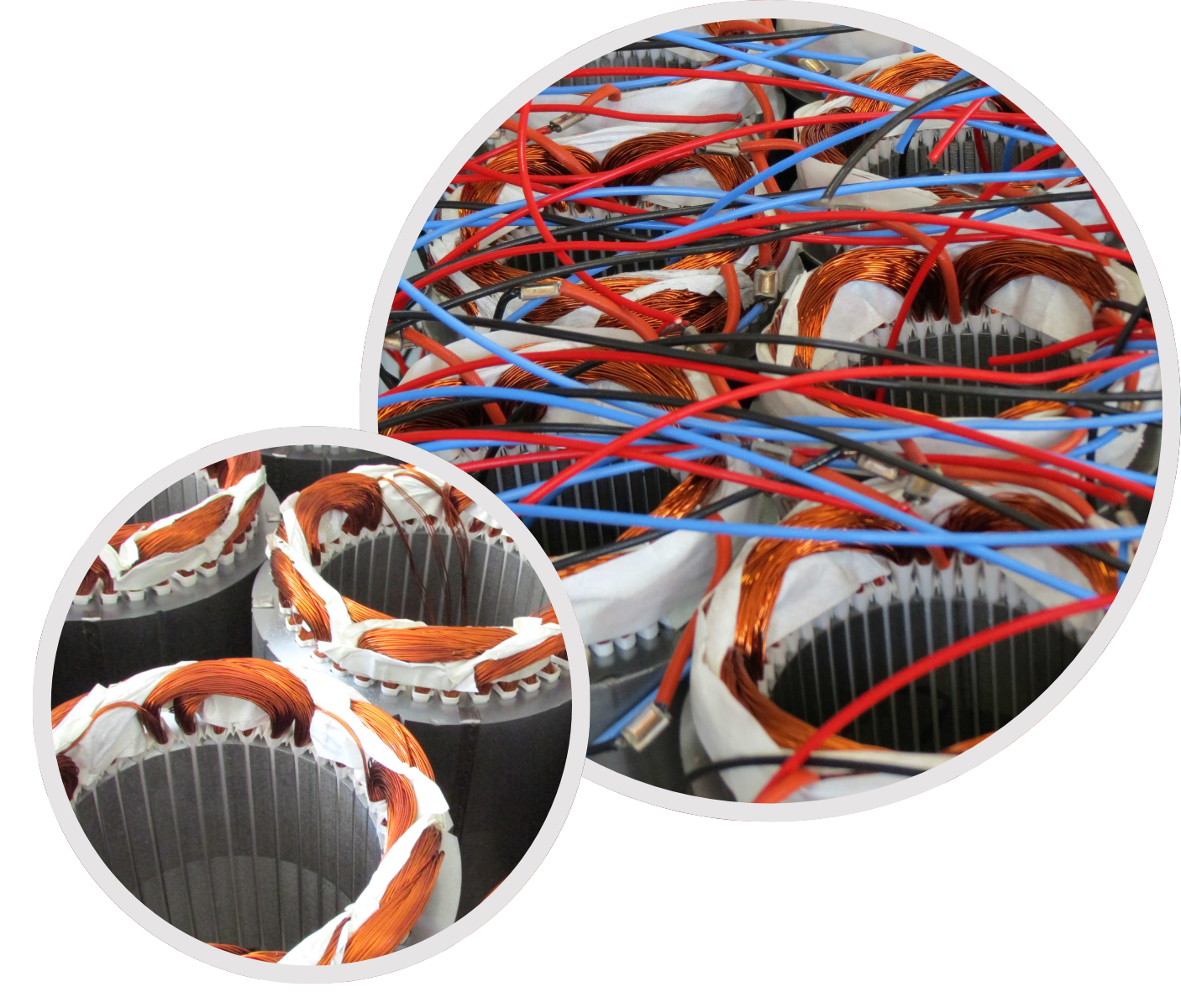

Modern machine tools such as automatic lathes, CNC machining centers and high speed milling machines demand exceptional levels of precision, repeatability and reliability from their electric motors. At the core of these performance requirements are the motor windings, which play a crucial role in ensuring stable motor operation and consistent production quality.

Key technical requirements for electric motor electric motor windings in machine tools

In high-intensity operating environments involving frequent starts and stops, sudden load variations and micron-level machining, windings must meet the following requirements:

- be perfectly balanced to minimize vibration;

- remain thermally stable to resist localized overheating;

- be custom designed based on machine configuration and application type.

Zampolli Avvolgimenti applies its proven expertise in high-performance spindle windings to the development of motor windings for advanced machine tools, with one clear objective, to guarantee uninterrupted, high-precision production.

Materials and technologies that enhance winding durability for machine tools

The thermal and mechanical stresses placed on machine tool motors demand careful selection of materials and construction methods.

At Zampolli Avvolgimenti, we use:

- high-conductivity enameled copper wire;

- class F or H thermal insulation, ensuring long-lasting performance even under high thermal loads;

- thermosetting impregnation resins applied through immersion systems, improving both dielectric strength and mechanical adhesion;

- manual coil insertion, allowing precise control of tolerances and uniform placement within the stator stack.

Every aspect of our process is designed to deliver high-performance windings that withstand even the most demanding operating conditions over time.

Where Avvolgimenti Zampolli are used in industrial machine tools

Our windings are employed in electric motors across a wide range of industrial machine tools, including:

- CNC machining centers for high-precision metalworking;

- automatic and semi-automatic lathes;

- high-speed milling machines;

- deep drilling and boring machines.

The quality of the windings has a direct impact on critical performance parameters such as spindle stability, motor dynamic response, and machining repeatability, key factors in precision engineering, aerospace, and automotive component manufacturing.

By custom-designing each winding to match the motor’s specifications, we optimize magnetic efficiency, reduce energy consumption, and extend the lifespan of the entire system.

Discover all our sectors

Why choose Zampolli for electric motor windings in machine tools

With over 50 years of craftsmanship and experience, Zampolli Avvolgimenti is a trusted partner in the production of non-standard electric windings, for special-purpose motors in the mechanical industry.

Choosing us means relying on a highly flexible, artisan-driven production process backed by direct technical support. We handle everything from one-off prototypes to small and special production batches with the same care and precision, responding swiftly to complex requests. Our team works closely with motor manufacturers’ R&D and engineering departments, offering expert consultation even during the design phase.

In an industry where mechanical precision is non-negotiable, the electric winding is the foundation of performance. It’s the starting point for building reliability, efficiency, and long service life, defining the difference between a standard machine tool and one engineered for superior results.

Do you need more info about our products?

We can produce a very wide range of asynchronous windings thanks to dedicated but flexible equipment.