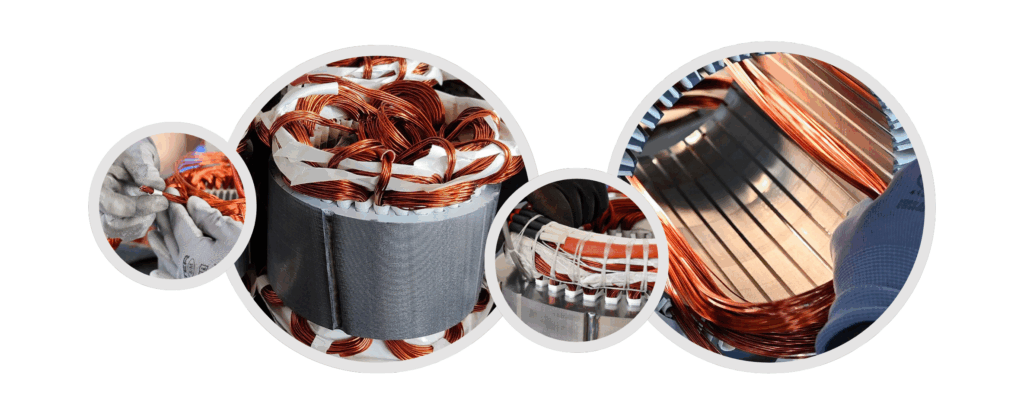

Custom electric motor windings

In many industrial applications, standard electric don’t meet the performance expectations. They may lack the required performance, fail to fit within spatial constraints, or fall short of regulatory standards.

That’s why more engineers and OEMs are turning to custom electric motors, solutions that depend on tailor-made windings, designed for seamless integration into complex environments. For over 50 years, Avvolgimenti Zampolli has specialized in handcrafted custom windings, delivering exceptional flexibility and a high level of personalization to meet demanding technical requirements.

Custom electric motor windings: when standard solutions fall short

Custom electric motors are required when standard models can’t meet specific needs: unusual power supplies, harsh environments, tight spaces, or high performance demands. In these cases, standard winding solutions aren’t enough, and custom-engineered windings are essential.

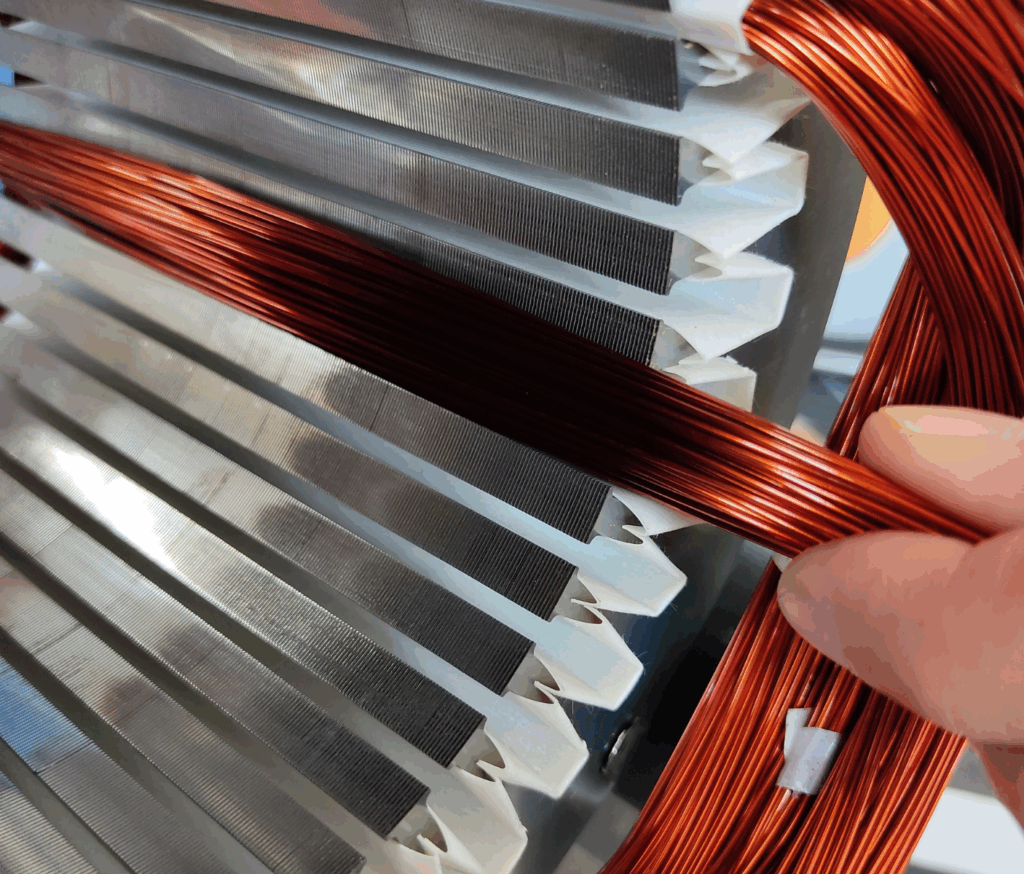

Zampolli designs and produces custom windings to each customer’s exact specifications. These often involve complex challenges like non-standard stator slots, irregular geometries, variable frequencies, and exposure to thermal or magnetic stress. We ensure reliability and performance using high-quality materials, optimized winding designs, and precise manufacturing techniques refined over decades.

Our flexible, manual production process allows us to deliver fully customized windings for both prototypes and small production runs. These are not just minor variations of standard windings but engineered solutions built for durability and top performance in demanding applications.

Handcrafted windings for custom electric motors

At Avvolgimenti Zampolli, every custom electric motor winding is made entirely by hand, drawing on decades of technical expertise that we continue to develop with each project.

The process starts with detailed technical documentation provided by the client. We carefully review this information together, offering suggestions for improvements based on our extensive experience with special windings.

Once the specifications are agreed upon, our skilled technicians begin production. Each step (winding coils, inserting them into stator slots, making electrical connections, and binding) is done manually with great care and precision, achieving a level of quality that automated industrial processes cannot match.

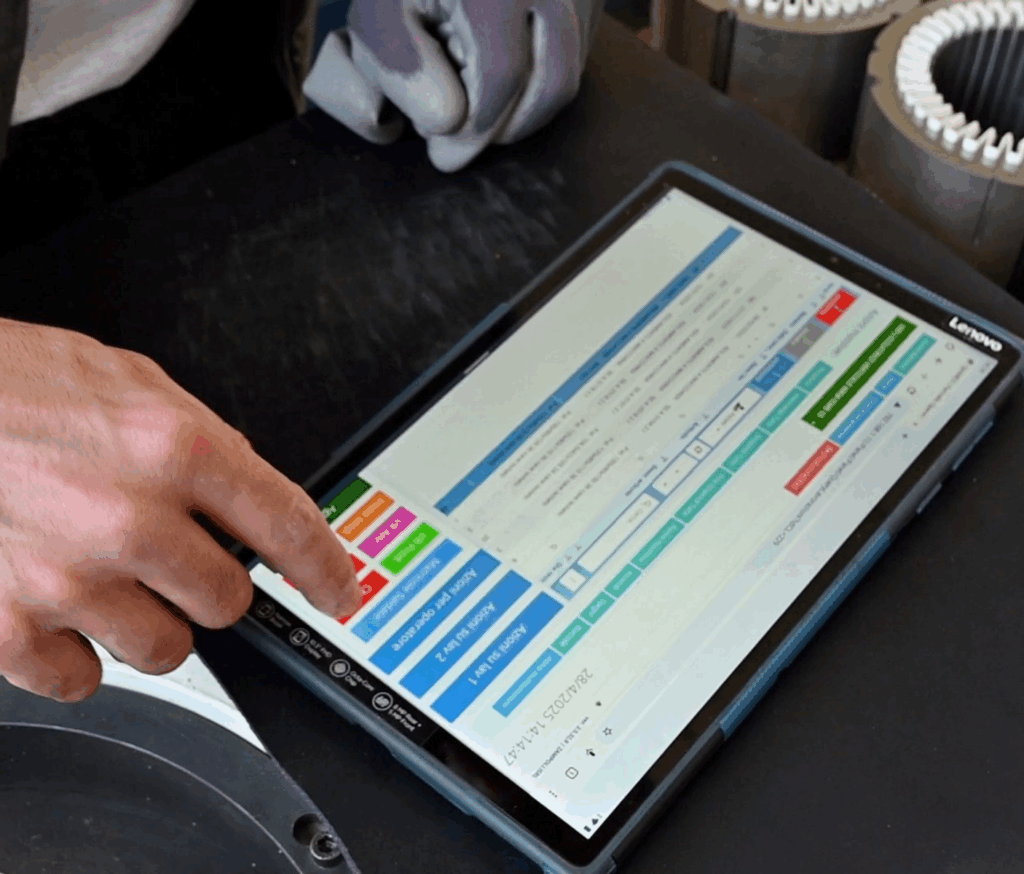

Throughout production, we perform strict quality control tests, including measuring ohmic resistance and phase inductance, as well as insulation and dielectric strength tests. These checks guarantee that every winding is electrically reliable and ready for integration.

Our focus is not only on technical accuracy but also on mechanical strength, durability, and compatibility with even the most demanding industrial environments. Every winding that leaves our workshop reflects a unique combination of technical knowledge, manual skill, and a strong commitment to excellence.

Avvolgimenti Zampolli: expertise, reliability and precision for custom electric motors

Our strength lies not only in our technical expertise and hands-on experience but, above all, in the close, collaborative relationships we build with each client.

Clear and ongoing communication is essential at every stage of the process. From the initial review of technical specifications, we work closely with R&D teams, technical departments, and industrial maintenance managers to define:

- the most suitable materials

- the optimal winding design

- the ideal insulation methods

- custom performance optimizations

This direct partnership, combined with our fully in-house production model, allows us to deliver fast turnaround times, precise execution, flexibility, and consistently certified expertly crafted results.

Contact us for your custom electric motor windings projects

Need a winding for a custom or non-standard motor? Send us your technical specifications.

Our team will promptly provide you with a detailed offer and deliver full technical support throughout the entire production process.

Do you need more info about our products?

We can produce a very wide range of asynchronous windings thanks to dedicated but flexible equipment.