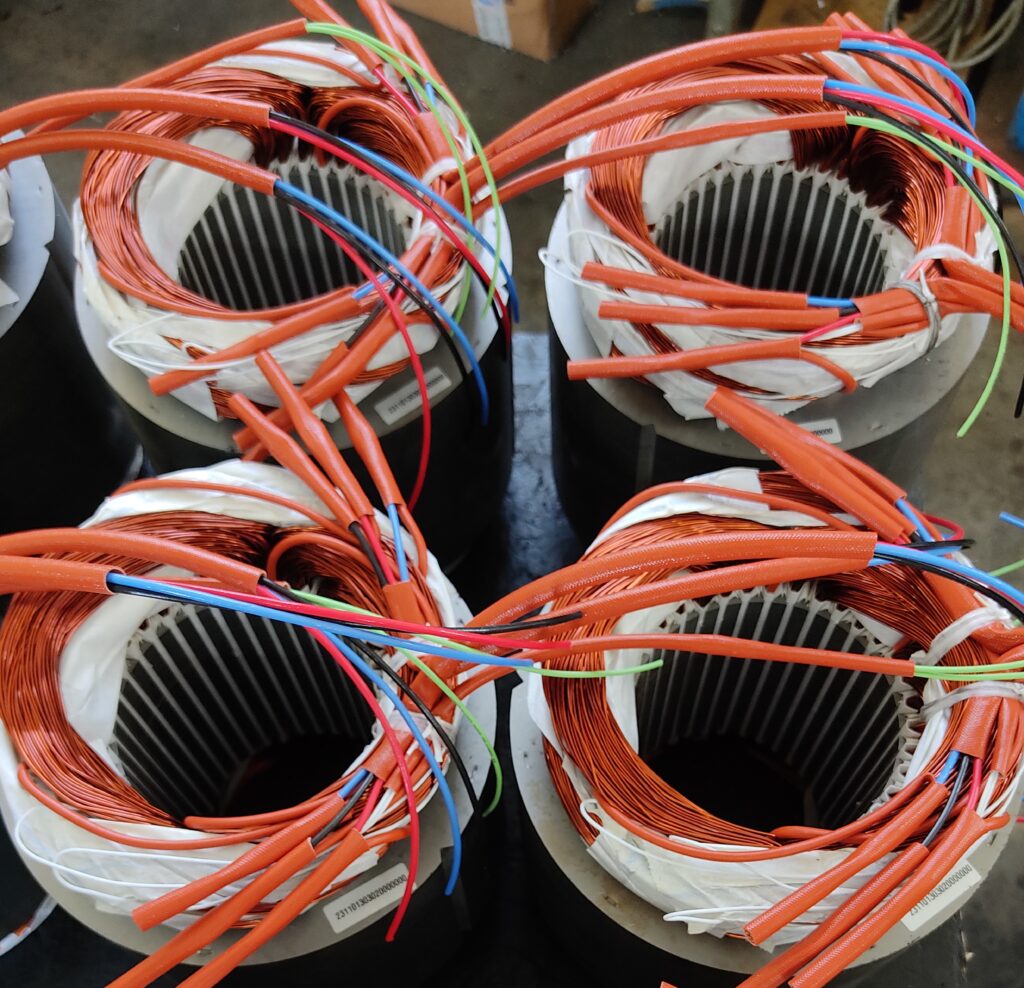

Electric motor windings

Avvolgimenti Zampolli specializes in the handcrafted production windings for alternating current (AC) motors, designed for a wide range of industrial applications.Our custom solutions are known for technical precision, exceptional build quality, and fast delivery times.

Each winding is meticulously crafted by highly skilled technicians using carefully selected materials and advanced insertion techniques, ensuring enhanced durability and reliable high performance.

Our motor windings are the ideal choice for three-phase asynchronous motors and specialized electric motors used in the automotive, railway, marine, agricultural, and industrial sectors.

craftsmanship of the product

continuous staff training

attention to customer needs

dedicated and punctual deliveries

AC Motor windings: handcrafted excellence, certified materials, and reliable performance

Avvolgimenti Zampolli specialises in the prototyping and production of AC electric motor windings, with a specialization in three-phase systems. This dedicated expertise allows us to deliver highly customized solutions and top-level technical precision for complex industrial applications. All of our resources and technical know-how are concentrated on AC systems, which today set the standard for reliability, energy efficiency, and long-term durability.

What sets us apart is not only the quality of our materials, including high-conductivity enamelled copper wire and Class F and H thermal insulation systems, but also the accuracy of our winding techniques. This precision is essential to ensuring maximum performance and full compliance with international standards.

Custom electric motor windings for reliability and optimized performance

Zampolli’s three-phase windings are engineered for high performance, long service life, and optimised energy efficiency,even in demanding operating conditions.

In addition to our standard windings, we manufacture fully customised solutions for motors with non-standard requirements, such as harsh environments, unusual speeds, unconventional working conditions, and prototype or research-driven applications.

Each special project is handled with the utmost care, from initial design through to final testing, to ensure a solution that’s fully aligned with the customer’s operational needs.

Our method for manufacturing electric motor windings

At Avvolgimenti Zampolli, our winding production process follows a series of carefully controlled steps designed to ensure the highest standards of quality and reliability:

RIGOROUS INSPECTION OF RAW MATERIALS

a fundamental step to guarantee winding quality from the start.

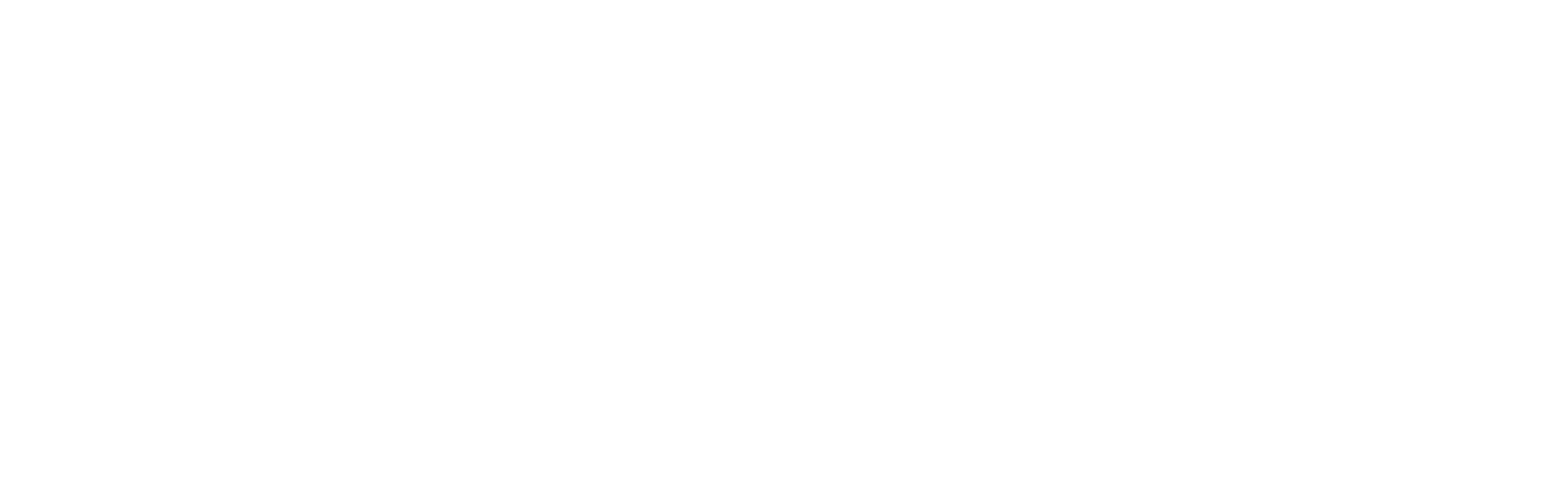

STATOR CORE INSULATION

applied manually or mechanically depending on stator size. This crucial process protects the winding from potential faults.

We maintain a stock of pre-insulated stator cores to enable rapid response to urgent orders.

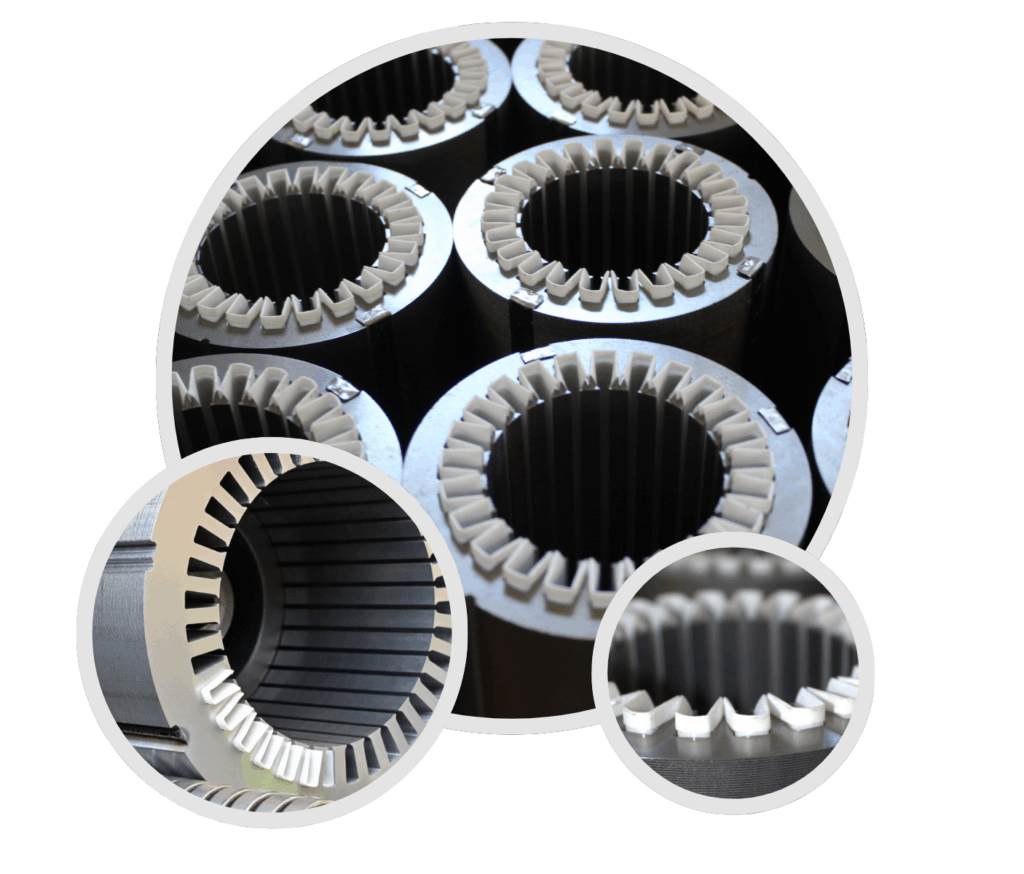

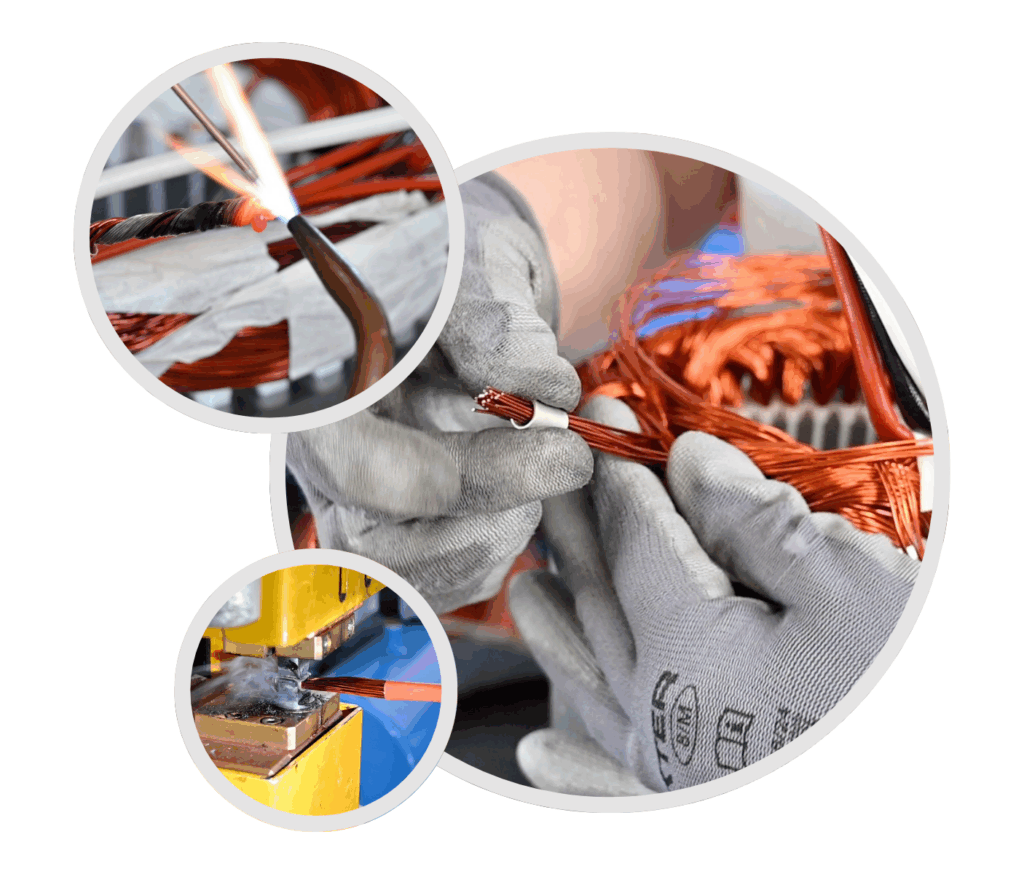

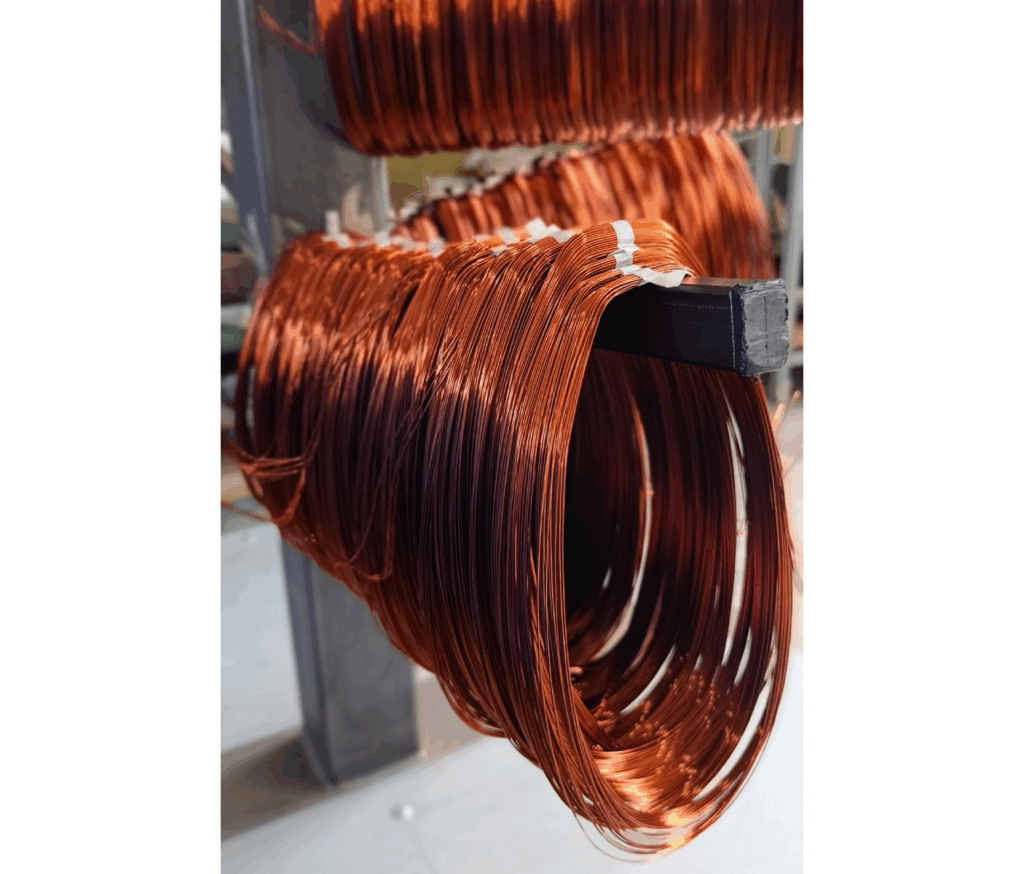

COPPER COIL PRODUCTION

carried out on specialised machines customised to the required coil dimensions. All coil winders are PLC-controlled to accurately store programmes and tooling settings, thereby minimising operator error.

Rigorous quality checks are performed on incoming copper wire and during the initial production cycles. End-of-wire sensors automatically halt the machine to maintain coil integrity.

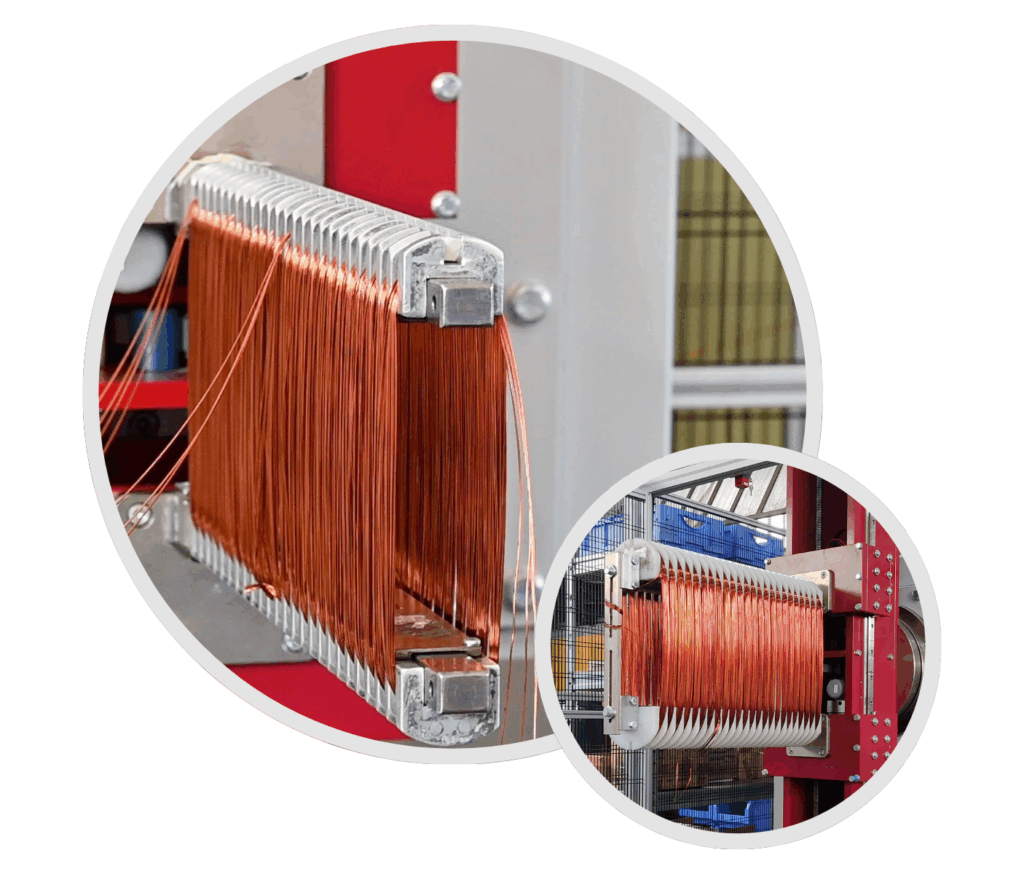

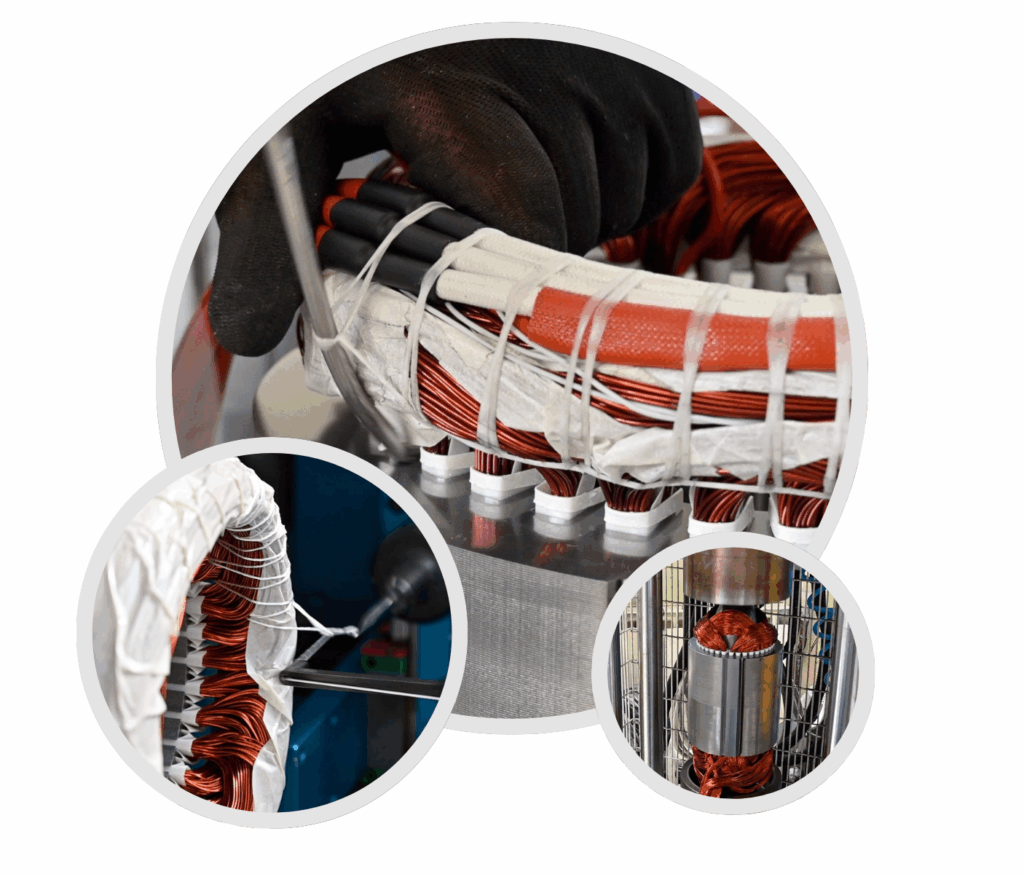

INSERTION OF COILS INTO THE STATOR

a delicate process still predominantly performed by hand (around 70% of our production). This manual method ensures high precision and flexibility, especially for specialised motors, with each coil carefully positioned to meet exact design specifications.

ELECTRICAL CONNECTIONS

Made using thermal compression machines for conductor sections up to 70 mm². For larger sections or specific customer requests, traditional flame soldering is used.

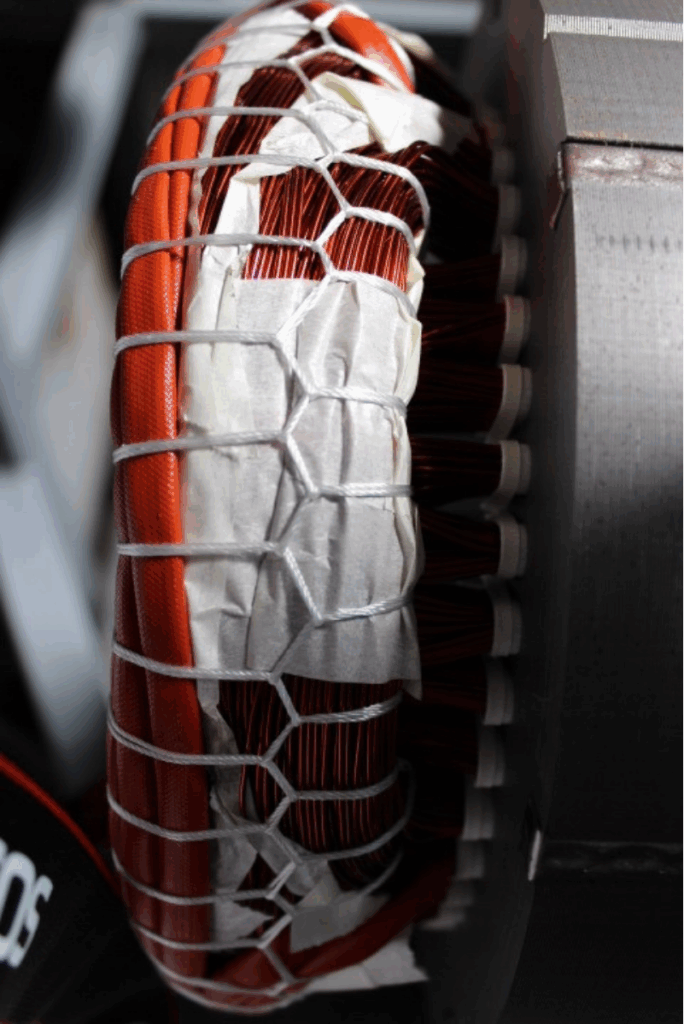

LASHING AND COIL HEAD FORMING

Performed either manually or mechanically, depending on winding size and client requirements.

Every winding undergoes 100% end-of-line electrical testing (EOL) to verify full functionality before the final stage. The last step is impregnation and curing: windings are impregnated with water-based varnish or resin and then oven-cured. This treatment provides excellent mechanical, chemical, and dielectric resistance.

Each stage of our process is vital to delivering electric motor windings that are efficient, reliable, and built to last.

The value of handcrafted electric windings

Manual production of electric motor windings remains a benchmark of quality, especially for applications requiring maximum reliability and precision. Unlike automated methods, the artisanal approach enables each winding to be precisely tailored to the motor’s geometric and functional requirements, compensating for manufacturing tolerances and optimising coil placement within the stator slots.

At Avvolgimenti Zampolli, highly skilled technicians insert coils by hand. This hands-on expertise provides a clear advantage: manually inserted windings withstand thermal stress, mechanical vibration, and frequent start-stop cycles, ensuring consistent peak performance even in the most demanding conditions.

Premium materials for high-efficiency motor windings

To guarantee the performance and reliability of our windings, we use only top-quality materials. This includes high-conductivity enamelled copper wire and Class F or H insulation systems, designed to withstand high thermal and electrical stress.

All production stages are subject to rigorous quality checks, ensuring safe, long-lasting, and efficient windings for demanding industrial applications.

Industrial applications for Zampolli motor windings

Avvolgimenti Zampolli are used in a wide range of industrial sectors, thanks to their versatility, mechanical strength, and adaptability to highly specific operating requirements.

Our solutions are especially in demand in the electric traction sector, where motors must deliver maximum reliability, durability, and performance under extreme environmental conditions.

We also manufacture windings for machine tools and electrospindles, where precision and mechanical durability are essential. In the rail and marine industries, our windings power propulsion, auxiliary, and service motors, all designed to meet the rigorous standards of continuous operation. Other key applications include: high-frequency vibratory motors, industrial pumps for fluid handling, brushless motors, where compactness, performance, and control accuracy are essential

Thanks to our ability to engineer and build fully customised windings, we meet even the most complex technical requirements, especially where off-the-shelf solutions are insufficient.This expertise has also brought us into the cutting edge of automotive e-mobility, supplying windings for luxury electric hypercars. These high-performance vehicles demand exceptional design precision, top-grade insulating materials, and complete process control: qualities that define every Zampolli winding.

To learn more about our specialised solutions, visit the dedicated pages on three-phase asynchronous motor windings and custom electric motors. You’ll find detailed technical insights and costumised solutions to the most demanding industrial challenges.

Choose Zampolli for high-quality electric motor windings

For over 50 years, Zampolli Windings has been a trusted name in the production of high-quality electric motor windings.

Founded on a tradition of Italian craftsmanship, the company has evolved by integrating modern technologies while remaining fully committed to quality, precision, and customer satisfaction.

Our extensive experience enables us to deliver customised winding solutions tailored to a wide range of industrial requirements.

This approach has earned us the trust of manufacturers and technical teams seeking reliability, performance, and flexible production support.

Contact us for your electric motor windings projects

Looking to improve the efficiency and performance of your industrial motors with custom-designed windings?

Get in touch with us today. Our team is ready to provide expert technical guidance and deliver solutions tailored to your specific operational requirements.

Do you need more info about our products?

We can produce a very wide range of asynchronous windings thanks to dedicated but flexible equipment.